Paper is an important basic material used in the printing industry. The quality of paper directly affects the quality of printed products. Due to the difference in pulp raw materials and papermaking processes used, there is a significant difference in the inherent properties of the paper produced. Even with the same type of paper, there is a clear difference in printability under different printing methods. The paper used for offset printing is mostly coated paper and offset paper. Coated paper has higher smoothness and whiteness than offset paper but has poor elasticity. In the printing process, the failure caused by the paper properties, the more common is the paper size stability is not good caused by overprinting is not allowed, the paper surface strength caused by the powder off the hair phenomenon, poor paper smoothness, uneven thickness caused by the flower Spot or whitening phenomenon.

One, paper size stability

During the production, transportation, and storage of paper, the paper will undergo certain deformation with changes in the temperature and humidity of the environment, forming phenomena such as "foliage" or "tight edges". Before printing on the machine, the paper is handled by hanging and hanging. Can effectively eliminate these faults. The misprinting caused by the paper's elongation and deformation during the printing process is the most common failure in offset printing. For offset printing, due to the existence of fountain solution, each time the printing, the paper must absorb a part of the water, the paper is subjected to wetting and produce a certain degree of elongation and deformation, the amount of this deformation is determined by the papermaking raw materials and processes, mainly The fiber content of the paper itself, fiber length and binding force, and the degree of sizing are all factors that determine the tightness and hygroscopicity of the paper and the compression properties of the paper. In general, the paper size changes within the allowable overlay error. For paper with high fiber content, short fibers, and unsatisfactory degree of sizing, the hygroscopicity is large; if the structure is loose and the tightness is not high, the compressive properties of the paper will exhibit approximately fluid properties when compressed. When the above paper has a large amount of water in the layout or the pressure of the big teeth is loose, the uneven force of wear occurs, and it is easy to cause serious deformation, so that the next color is not overprinted and waste products are produced. The performance of the paper is determined by the production of the paper. Therefore, the printing mainly controls the moisture of the plate and adjusts the mechanical pressure to reduce or warp the deformation of the paper and improve the printability of the paper. The layout of the water control, generally the layout is gray, slightly reflective, you can try to use the minimum amount of water to maintain the ink balance, if the water is too easy to paste version. The monochrome offset press should pay special attention to the moisture control and control the deformation of the paper to a minimum to facilitate the accuracy of the next color overlay. We used a US imported 80g coated paper printing trademark, which produced extremely severe lateral stretch deformation when the eight-version printing machine was used on a split monochrome machine, and the next color could not be put on. The paper is visually and well-feeling. It is estimated that the use of wood for pulp, high degree of pulping makes the fiber deuteration, short, thin fiber content, so that the paper has a strong hygroscopicity, resulting in paper water absorption elongation. After using the four-color printing machine to print in two versions, there is still some chromaticity error. This highly deformed paper cannot be used for fine dot printing. As a result of the poor compression properties of the paper, uneven tension, weak bonding force between the fibers and resulting in the elongation and deformation in the printing direction, the deformation can be effectively reduced by reducing the printing pressure and adjusting the dent force.

Second, the surface strength

The surface strength of the paper refers to the strength of the bond between the fibers, the filler and the compound, which reflects the ability of the paper to resist powder-off and hair loss. It is determined by the papermaking materials and processes, and the selection and pressure of the filler compound. The degree of light and other factors. For example, in broad-leaved pulp, catheters with weak binding force to fibers often fall off during printing. As for the use of inorganic filler paper, because the filler itself has no binding force, it is easy to produce powder off. We had this kind of situation when we printed a certain kind of drug label. When printing hundreds of sheets, the blanket was covered with a lot of paper hair. Even if a viscosity-reducing agent was used, it could not be eliminated. With your fingers on the paper, the fingers will be covered with a layer of paper, indicating that the filler does not bond well with the paper. Afterwards, the printing ink was used to reduce printing pressure, and thousands of blankets were printed on the blanket to complete the printing job. Coated paper is less likely to lose powder. However, if the coating layer and the paper base are not well bonded, large-area peeling may occur due to the high viscosity of the ink. Paper off and lint is also related to ink viscosity, print pressure, and print speed. The method of reducing the viscosity and reducing the pressure is usually adopted, which can effectively reduce the paper powder off hair phenomenon.

Third, smoothness, thickness

The smoothness is the degree of evaluation of the surface roughness of the paper, and the thickness is the degree of the paper thickness. Smoothness is closely related to the transferability of ink. Offset printing is done with a very good elastic blanket. To a certain extent, it can make up for the unevenness of the paper surface. The ink can be transferred to the paper better. However, when the high-grade print is printed, smoothness is often used to avoid damage to the graphic layer. Very high coated paper, because the smoothness of the paper, the printing ink color saturation, good gloss. The clarity of the image is high and the quality of the print is good. As for offset paper, the smoothness of offset paper produced by different manufacturers varies greatly. Some offset papers have poor smoothness, and the thickness is not uniform. When hard liners are used as liners, ink transfer is insufficient, resulting in different shades of blotting, resulting in unsightly variegated spots, and even whitening when severe. Because it is easier to print small spots when printing offset paper, in the printing, frequent inspections should be made. Frequently, small dots or uneven prints are uneven. Ink prints with uneven colors should be appropriately printed. Pressure, increase the flow of ink, but pay attention to control the amount of ink, so as not to cause paste phenomenon.

The performance of the paper that affects the quality of the printed product is also the properties of the paper such as ink absorbency, whiteness, sizing degree, and acidity and alkalinity. The above analysis is mainly focused on failures that often occur in actual operations. In the procurement of paper and ordering, we must choose papers with good printability so as to reduce the quality of prints.

One, paper size stability

During the production, transportation, and storage of paper, the paper will undergo certain deformation with changes in the temperature and humidity of the environment, forming phenomena such as "foliage" or "tight edges". Before printing on the machine, the paper is handled by hanging and hanging. Can effectively eliminate these faults. The misprinting caused by the paper's elongation and deformation during the printing process is the most common failure in offset printing. For offset printing, due to the existence of fountain solution, each time the printing, the paper must absorb a part of the water, the paper is subjected to wetting and produce a certain degree of elongation and deformation, the amount of this deformation is determined by the papermaking raw materials and processes, mainly The fiber content of the paper itself, fiber length and binding force, and the degree of sizing are all factors that determine the tightness and hygroscopicity of the paper and the compression properties of the paper. In general, the paper size changes within the allowable overlay error. For paper with high fiber content, short fibers, and unsatisfactory degree of sizing, the hygroscopicity is large; if the structure is loose and the tightness is not high, the compressive properties of the paper will exhibit approximately fluid properties when compressed. When the above paper has a large amount of water in the layout or the pressure of the big teeth is loose, the uneven force of wear occurs, and it is easy to cause serious deformation, so that the next color is not overprinted and waste products are produced. The performance of the paper is determined by the production of the paper. Therefore, the printing mainly controls the moisture of the plate and adjusts the mechanical pressure to reduce or warp the deformation of the paper and improve the printability of the paper. The layout of the water control, generally the layout is gray, slightly reflective, you can try to use the minimum amount of water to maintain the ink balance, if the water is too easy to paste version. The monochrome offset press should pay special attention to the moisture control and control the deformation of the paper to a minimum to facilitate the accuracy of the next color overlay. We used a US imported 80g coated paper printing trademark, which produced extremely severe lateral stretch deformation when the eight-version printing machine was used on a split monochrome machine, and the next color could not be put on. The paper is visually and well-feeling. It is estimated that the use of wood for pulp, high degree of pulping makes the fiber deuteration, short, thin fiber content, so that the paper has a strong hygroscopicity, resulting in paper water absorption elongation. After using the four-color printing machine to print in two versions, there is still some chromaticity error. This highly deformed paper cannot be used for fine dot printing. As a result of the poor compression properties of the paper, uneven tension, weak bonding force between the fibers and resulting in the elongation and deformation in the printing direction, the deformation can be effectively reduced by reducing the printing pressure and adjusting the dent force.

Second, the surface strength

The surface strength of the paper refers to the strength of the bond between the fibers, the filler and the compound, which reflects the ability of the paper to resist powder-off and hair loss. It is determined by the papermaking materials and processes, and the selection and pressure of the filler compound. The degree of light and other factors. For example, in broad-leaved pulp, catheters with weak binding force to fibers often fall off during printing. As for the use of inorganic filler paper, because the filler itself has no binding force, it is easy to produce powder off. We had this kind of situation when we printed a certain kind of drug label. When printing hundreds of sheets, the blanket was covered with a lot of paper hair. Even if a viscosity-reducing agent was used, it could not be eliminated. With your fingers on the paper, the fingers will be covered with a layer of paper, indicating that the filler does not bond well with the paper. Afterwards, the printing ink was used to reduce printing pressure, and thousands of blankets were printed on the blanket to complete the printing job. Coated paper is less likely to lose powder. However, if the coating layer and the paper base are not well bonded, large-area peeling may occur due to the high viscosity of the ink. Paper off and lint is also related to ink viscosity, print pressure, and print speed. The method of reducing the viscosity and reducing the pressure is usually adopted, which can effectively reduce the paper powder off hair phenomenon.

Third, smoothness, thickness

The smoothness is the degree of evaluation of the surface roughness of the paper, and the thickness is the degree of the paper thickness. Smoothness is closely related to the transferability of ink. Offset printing is done with a very good elastic blanket. To a certain extent, it can make up for the unevenness of the paper surface. The ink can be transferred to the paper better. However, when the high-grade print is printed, smoothness is often used to avoid damage to the graphic layer. Very high coated paper, because the smoothness of the paper, the printing ink color saturation, good gloss. The clarity of the image is high and the quality of the print is good. As for offset paper, the smoothness of offset paper produced by different manufacturers varies greatly. Some offset papers have poor smoothness, and the thickness is not uniform. When hard liners are used as liners, ink transfer is insufficient, resulting in different shades of blotting, resulting in unsightly variegated spots, and even whitening when severe. Because it is easier to print small spots when printing offset paper, in the printing, frequent inspections should be made. Frequently, small dots or uneven prints are uneven. Ink prints with uneven colors should be appropriately printed. Pressure, increase the flow of ink, but pay attention to control the amount of ink, so as not to cause paste phenomenon.

The performance of the paper that affects the quality of the printed product is also the properties of the paper such as ink absorbency, whiteness, sizing degree, and acidity and alkalinity. The above analysis is mainly focused on failures that often occur in actual operations. In the procurement of paper and ordering, we must choose papers with good printability so as to reduce the quality of prints.

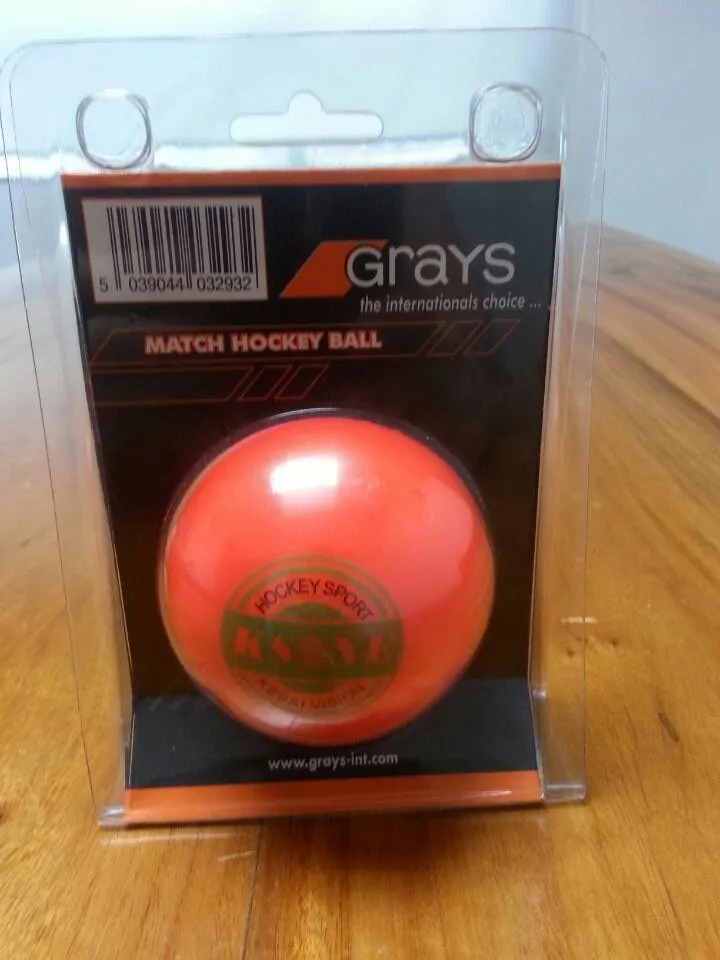

PVC Smooth Indoor Hockey Ball

Product Description

An excellent quality dimpled ball molded with stand out colors. Suitable for matches and training on all surfaces. Volume discount available. Available in two colors, orange or white.

| Function: | Indoor hockey (smooth floor) |

| Material: | PVC |

| Color: | White/Orange |

| Size: | 71mm in Diameter |

| Logo: | Customizable |

| MOQ: | 500 pieces |

| Sample Time: | (1) 7 working days-If need customized logo. |

| (2) Within 1working days- for existing samples | |

| OEM Service: | Yes |

| Certification Available: | Yes |

| Packing details: | 120PCS/CTN |

Dimple Hockey Ball

Weight :between 156-- 163 grams

Diameter:73±1mm

Surface: Dimple/smooth

Q'TY/CTN:120/PC

MEANS(CM): 52*38*39.5cm

·2014 Holland Hockey World Cup Authorized Supplier

·Smooth Ball, Better Performance on Indoor Floor

·Individual Packaging

Our company

Fayyou Sport Co., Ltd.,subsidiary of Zhuhai Kesai Co Ltd. founded in 1997, is specialized in producing and promoting sports products including lacrosse,hockey, crossfit and massage products.

Kesai has professional experience in manufacturing, marketing and shipping, providing multiple services. Fayyou Sport was established in 2015 due to increasing sports business volume.

Shipping

Packing

Hockey Ball

Massage Spiky Ball,Roller Spiky Ball,Spiky Massage Ball,Rolling Massage Ball

FAY YOU SPORTS CO.,LTD , http://www.ksonelacrosse.com